Mastering Vertical Material Handling: Choosing the Right Equipment – Vol. 03

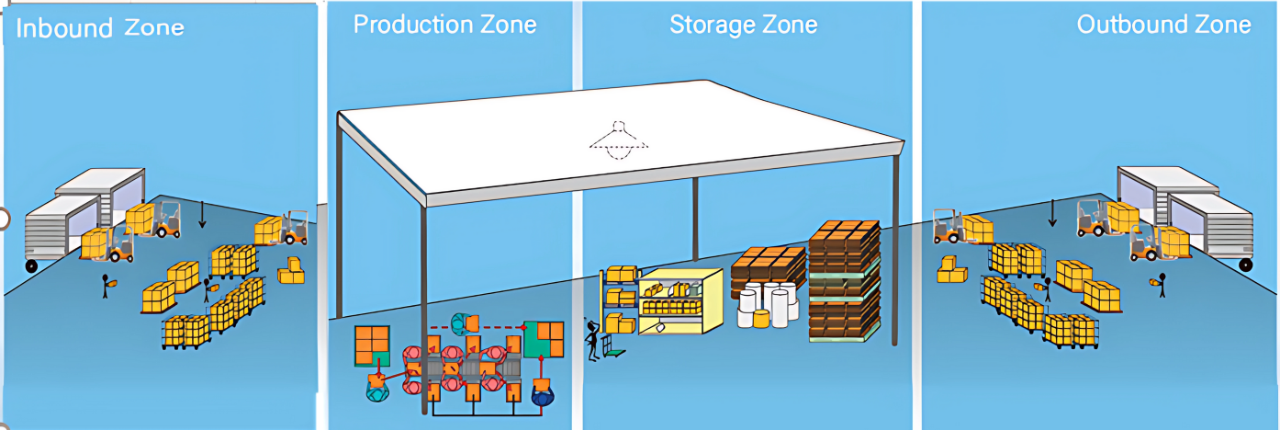

Storage area in any warehouse or factory is key for operational efficiency. In this guide, we’ll explore the different material handling equipment suited for low to medium level stacking, including forklifts and stackers.

Why Vertical Material Handling Matters for Your Business:

Easily accessible and efficient material storage is crucial for any business that deals with inventory management, warehousing, or industrial operations. Maximizing vertical space allows you to store more products in a given storage area, improve inventory management of raw materials/finished goods, and enhance overall operational efficiency and space utilization.

The selection of the right material handling equipment for vertical movement of material depends upon:

- Size and weight of material

- Indoor and outdoor application

- Last height of loading

- Type of racks

- Aisle space available

- Through-put requirement of the operation etc.

In this guide, we give you an insight to the different types of material handling equipment available for vertical movement and general guideline to choose the right equipment based on application demand.

Best Equipment for Vertical Material Handling: An Overview:

There are different material handling equipment options available to serve your requirements. Selecting the right equipment for vertical storage ensures safe and efficient movement of products. Let’s dive into the most commonly used equipment for vertical movement of material in warehouses,factories, and other applications.

1. Diesel Forklift Trucks: Heavy-Duty Vertical Movement

Diesel forklifts are built for low to heavy-duty operations by providing high lifting power and robust performance. They are best suited for outdoor operations, especially where large and heavy loads need to be handled.

Preferred Work Environment:

- Outdoor applications

- Various attachments for handling non-palletized loads

- For low to medium level stacking

- Continuous operations

Key Features:

- High lifting capacities

- Resilient to extreme temperature variations

- Ideal for outdoor use, with rugged durability

- Roads which have some undulations

2. Battery Forklift Trucks: Quiet, Efficient, and Eco-Friendly

Zero emissions and quiet operations make battery-operated forklifts an excellent choice for indoor applications in warehouses, manufacturing facilities, retail industries, and distribution centres. They come in 3-wheel and 4-wheel designs to meet specific application requirements.

Preferred Work Environment:

- Indoor or occasionally outdoor applications

- Various attachments for handling non-palletized loads

- Cold storage facilities & freezer applications

- Clean and hygienic operations (Food/Pharma)

Key Features:

- Eco-friendly and low-emission operation

- Suitable for indoor environments with tight spaces

- Lower operational costs compared to diesel forklifts

3. Stackers: Compact and Agile for Tight Spaces

Compact and Agile for Tight Spaces Stackers are ideal for confined areas and navigating narrow aisles in high-density storage areas. Ease of manoeuvring and ergonomic design make stackers the preferred choice for low to medium racking storage. They are also used for loading and unloading goods from trucks, trailers, and containers. Stackers come in different specifications to suit various material handling requirements. Some common types of stackers include:

- Manual Stackers

- Semi-Electric Stackers

- Electric Stackers (walkie/platform/operator compartment)

- Wide Straddle Stackers

- Elevating support arm Stackers

- Counterbalance Stackers

Stackers can handle open-type pallets only (except counterbalance stackers). Counterbalance stackers can handle both open and closed-type pallets.

Preferred Work Environment:

- Pallet stacking

- Material movement in confined areas

- Underground or mezzanine floor applications

- Cold storage facilities & freezer applications

Key Features:

- Lightweight and easy to manoeuvre

- Designed for narrow aisles and small spaces

- Manual or battery-powered options available

Key considerations while choosing equipment for vertical handling of loads

When selecting the right equipment for vertical material handling, keep these essential factors in mind:

- Type of goods

- Load weight and size

- Type of floor

- Type of pallets

- Lifting height

- Indoor vs. outdoor use

- Space availability

- Work intensity

Conclusion: Boost Your Warehouse Efficiency with the Right Equipment

Choosing the right equipment for horizontal movement and vertical stacking (up to 6m) can significantly improve your warehouse's productivity and space utilization. Whether you need to lift heavy loads outdoors or efficiently organize your inventory in tight spaces, selecting the right forklift or stacker is essential to optimizing the operations.

Need help finding the perfect vertical material handling equipment for your business? Contact us today at marketing@tmhin.toyota-industries.com to explore our full range of material handling solutions. Optimizing vertical material handling in your warehouse or factory is essential for better storage space utilization and improving operational efficiency.

Ensure safe working condition for people working around. Whether you're moving heavy materials to high shelves or organizing products in a multi-level warehouse, choosing the right equipment for stacking and vertical movement is critical.

- December 9, 2024