Understanding your Material Handling needs A guide to select the Right Equipment – Vol.02

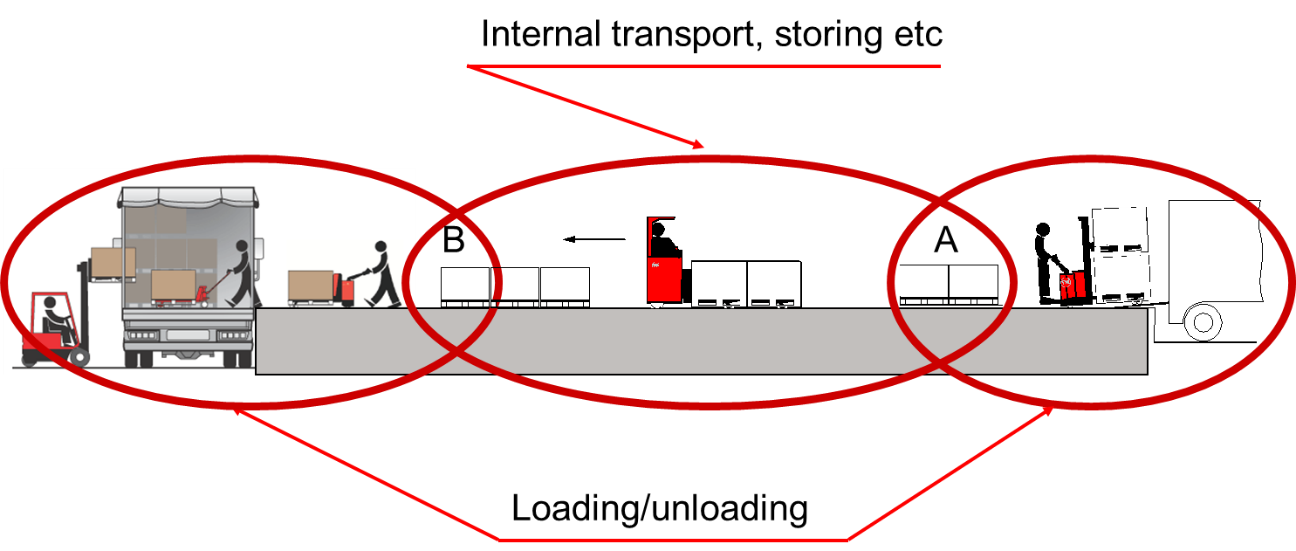

In any Industry, movement of material from one place to the other is quite common and essential activity. Efficient and safe handling of heavy material becomes imperatively critical for any industry. Hence, selection of right material handling equipment for such applications becomes crucial for any industry.

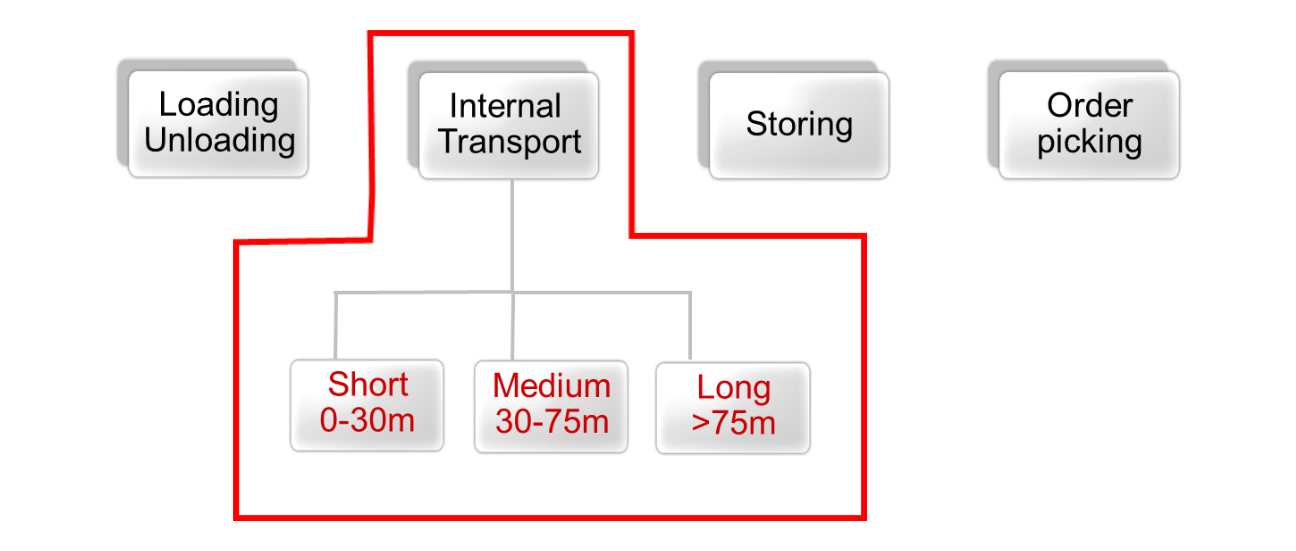

Selection of right material handling equipment for internal horizontal transport depends upon distance to be travelled.

- For Short Distance:

Hand Pallet or Battery-Operated Pallet Truck (Walkie Version)

- For Medium Distance:

Battery Operated Pallet Truck (Platform Version)

- For Long Distance:

Battery Operated Pallet Truck (Platform Version) or Tow Truck

Understanding the application and product features is key to identify and select right product for material handling needs.

Common material handling equipment utilized for horizontal internal transport:

1. Hand Pallet Trucks:

These are the basic entry level material handling equipment used to move material for short distances. Easy to operate and manoeuvre, they're perfect for smaller jobs in tight spaces.

Uses: Loading and unloading trucks, shifting pallets around, and moving goods within the warehouse.

2.Battery Operated Pallet Trucks (BOPT):

BOPTs are the next level equipment for medium and long distance hauling. Both the lift-off of the pallet from ground and the horizontal movement are motorized. This avoids the manual effort from the operators, thereby increasing the productivity.

BOPTs are available in platform and walkie versions. Walkie version is ideal for short ~ medium distances and platform version is used for medium ~ long distances, keeping productivity and operator comfort in mind.

Uses: Production to storage area or vice-versa, Loading and Un-loading from container etc.

3. Tow Trucks:

Towing tractors are material handling equipment designed to transport goods horizontally by towing loads on trollies. Available in wide range for handling different load capacities for different applications.

The operator position varies from walkie to stand-in or seated. The walkie models are designed for easy access and for shorter trips like towing chain of empty hand trolleys at airport, while the stand-on versions are used for applications involving frequent getting on and off the truck like in case of feeding different workstations in an assembly line. The seated versions are suited for long distance hauling without getting on & off the truck in between.

Uses: Towing movement of trollies in manufacturing, logistics (including Airports), warehouse etc.

4. AGV (Automated Guided Vehicles):

Automated Guided Vehicles (AGVs) are driverless vehicles used for material handling tasks. Relying on programmed instructions, predefined zones and sensors to navigate and carry out specific tasks. They are specifically designed to handle repetitive tasks within various operations.

Uses: For pre-defined zones, and specific repetitive movement in closed warehouse or factory area.

Got queries or need help in finding the right equipment? Contact Us Now:

or Drop us a line at marketing@tmhin.toyota-industries.com . We're here to make sure your material transport game is top-notch.

- July 9, 2024